The central AC compressor is no doubt the most crucial component of any central AC unit. Your AC would not function without it.

Perhaps you’ve noticed that some HVAC technicians claim AC compressor repairs and replacements are complex and costly, statements that seem like they’re trying to upsell you.

They certainly are not; this is one critical part of your cooling system.

call 661-888-0248

Contact us 24/7 for HVAC services!

In this post, we explain some common queries to help you understand the benefits of your compressor.

We hope to help you maintain a properly functioning central AC unit compressor.

Let’s go.

What is a Central AC Compressor?

The central AC compressor is the “heart” of your cooling system or heat pump. It is the component that circulates the refrigerant throughout the system. Therefore, if your house isn’t cooling, it’s likely that the problem originates from the central air compressor.

Your central AC or heat pump system contains an inside coil, an outside coil, and a series of lines that link the two.

The compressor is the equipment that circulates refrigerant via the line set from coil to coil. It is found in the outdoor unit, also known as the condensing unit.

How Does a Central AC Compressor Work?

To understand how AC compressors operate, we first need to go through the essential components of your heat pump or AC system.

Refrigerant

The refrigerant liquid evaporates quickly, transforming into a low-pressure gas that gathers heat and attracts cooler air. It is the house AC compressor that facilitates the compressing of the refrigerant liquid.

The process is similar to how wet skin feels fantastic in the breeze. That’s water evaporating, getting rid of heat, and keeping you cool.

Evaporator Coil

Within your house, in the furnace or air handler, is a coil that looks like a radiator. Although there are various designs, many coils are A-shaped with sloping ends.

Once the refrigerant reaches the evaporator coil, it evaporates into a low-pressure gas. It then absorbs ambient heat from your house to provide cooled air. The blower motor is what pushes chilled air into your ductwork while simultaneously drawing in heated air to be cooled.

Aside from that, the evaporator coil becomes very cold, and moisture from the air condenses on it. However, the water drains away as it goes down the slope of the A-coil.

A central AC system cools and dries the air in your house, and dry air is more pleasant than moist air.

Also read: How to clean the evaporator coils.

Refrigerant Line Set

Although lines connecting coils are often copper, certain kinds of AC also employ synthetic materials. One line transports refrigerant vapor from the evaporator coil to the outdoor condensing coil. The other line transports refrigerant that has been cooled from the condenser unit to the indoor evaporator coil.

Condensing Unit

It houses the compressor outdoors and serves one critical function: contracting the high-pressure gas vapor back into a low-pressure gas.

When the refrigerant vapor is compressed, its temperature increases since the same amount of heat in less “space” makes it hotter. It becomes so heated that the outside air is cooler than the refrigerant on a hot summer day.

Heat wants to balance out, going from hotter to cooler regions. Therefore, heat must exit the refrigerant. The heat is delivered by the outside coil, similar to a radiator.

The outside coil features fins to increase its surface area and facilitate rapid heat transfer to the surrounding air.

Additionally, the refrigerant pressure is increased by vapor compression. According to physics, substances move from a region of high pressure to one of lower pressure (1). The pressure difference between the outside and interior units causes the refrigerant to flow through the unit.

Inside, the refrigerant gathers extra heat to transmit outside. When an air conditioning cycle is running, the process is continuous.

Models of Central AC Compressors

This tutorial covers the five different types of central AC compressors.

They include:

- Scroll compressors;

- Rotary compressors;

- Reciprocating compressors;

- Screw compressors; and

- Centrifugal compressors.

Understanding these models is excellent when you need help fixing a central air conditioner.

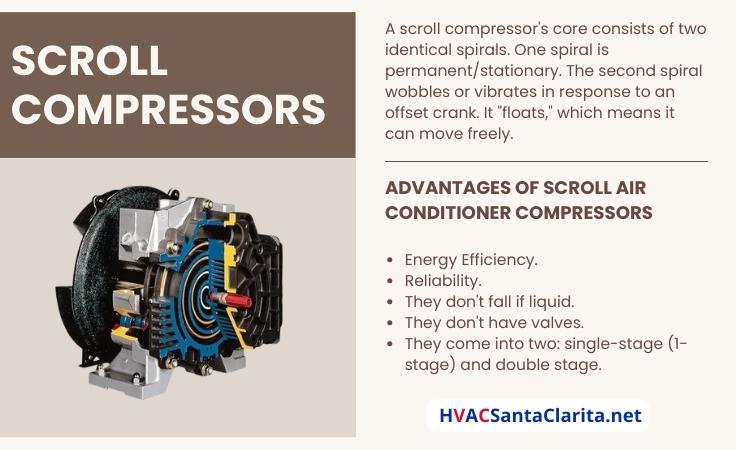

Scroll Compressors

They are the most popular compressors on the market. In AC replacement, technicians tend to use them as replacements when other compressors malfunction.

Many HVAC technicians believe the Copeland UltraTech Scroll compressor is the best in class. So, you may want to review it at your local home improvement store.

How does a scroll compressor function?

A scroll compressor’s core consists of two identical spirals. One spiral is permanent/stationary. The second spiral wobbles or vibrates in response to an offset crank. It “floats,” which means it can move freely.

As the rotating spiral turns, the refrigerant is compressed into a high-pressure vapor.

The vapor is driven toward the center of the compressor, getting denser and more compressed as it goes. In the middle, it exits the compressor for circulation across the system.

Advantages of Scroll Air Conditioner Compressors

- Energy Efficiency

- Reliability

- They don’t fall if liquid

- They don’t have valves

- They come in two stages: single-stage (1-stage) and double-stage

Rotary Compressors

They are what we often refer to as ductless AC units and heat pumps.

How Does a Rotary Compressor Function?

Rotary compressors, cylindrical in form, differ from scroll compressors in that they have suction and discharge ports connected to the refrigerant lines. A rotating compressor receives and releases refrigerant through the suction and discharge lines.

Inside the cylinder, an internal roller attached to the motor shaft rotates at the same speed as the motor, also known as the compressor shell. The roller’s width is less than that of the cylinder.

As the roller revolves, the offset crank interacts with the inner surface of the cylinders. By doing this, the refrigerant vapor is trapped and compressed. A spring-loaded vane is placed against the roller side, preventing the compressed refrigerant gas vapor from exiting and ensuring that it remains compressed.

The gas pressure will surpass that of the discharge line, and the vapor will be released to loop back to the evaporator coil. The suction valve opens, enabling more refrigerant to enter. This cycle is always continuous.

Advantages of a Rotary Compressor

- They are highly efficient

- They optimize indoor comfort

- They are quiet

Reciprocating Compressors

These are vintage compressors. They were often in use in conjunction with R22 refrigerants. However, due to the phase-out of R22, reciprocating compressors are less popular than rotary and scroll compressors.

Reciprocating implies that the pistons in the compressor travel back and forth inside a cylinder. We also refer to them as positive-displacement and piston compressors.

The suction manifold is where refrigerant gas enters from the low-pressure side. A crankshaft drives the piston up and down, compressing the gas before it is expelled. The pressure inside the compressor causes the valves on either side to open and shut.

The piston’s upward movement closes the suction valve and traps vapor in the compressor. The discharge valve must be pushed open to release the steam when the pressure within the compressed gas exceeds the pressure inside the discharge line.

This draws in additional vapor through the suction line and valve.

Advantages of a Reciprocating Compressor

The key advantages are that the design is simple and has consistent performance. ReciprocatinRg compressors come in various sizes, allowing them to be utilized in home units ranging from 1 to 5 tons and larger commercial air conditioners.

Screw Compressors

This is a huge commercial compressor, commonly known as a rotary screw compressor. This unit comprises two revolving helical screws that interlock. When gas vapor enters from the suction side, the screw action compresses and pushes the vapor from the big opening into the small opening.

The valve opens when the internal pressure exceeds the pressure in the discharge line, expelling the vapor. The process continues as the system draws more refrigerant gas into the suction side.

Advantages of a Screw Compressor

The key advantages are their simple design, dependability, and size. Rotary screw compressors are a common tool in commercial applications, ranging in size from 10 to 20 tons.

Centrifugal Compressors

These devices use a piston and cylinder to pull refrigerant into their compressor. A crankshaft spins a rotary impeller, forcing the refrigerant to turn rapidly. This squeezes the refrigerant in the cylinder before it is discharged. It then draws more from the suction side.

Advantages of a Centrifugal Compressor

These are more energy efficient and less expensive to produce than conventional commercial compressors.

Centrifugal compressors also produce a more consistent airflow than reciprocating compressors.

AC Compressor Maintenance

All compressor models require regular maintenance to ensure maximum efficiency and prevent mechanical problems. Remember that a heat pump is the same as an air conditioner. It may reverse the process by trapping heat outside in the winter and discharging it inside.

We highlight this because heat pump compressors are similar to AC compressors. Therefore, your heat pump compressor requires the same level of maintenance.

In our years of performing emergency AC unit repairs, we have found that issues often arise from poor or no maintenance of the AC compressor.

Reasons for Central AC Compressor Maintenance

- Inspect the suction and discharge pipes for leaks around the seals.

- Clean the coils of both the interior and outdoor units.

- Replace the air handler’s air filter as required.

- Clean the condenser unit jacket’s louvers.

- Inspect the refrigerant level annually.

- Wrap the condenser unit with an insulated blanket during winter.

- Flip the high-pressure switch in summer if your unit has one.

- Protect the condenser from direct sunlight.

- Remove any plants, shrubs, or overhanging tree branches that may obstruct airflow into the condenser.

From these benefits, you can see that the process of cleaning the central AC also involves cleaning the outside compressor.

Frequently Asked Questions

Why Is My Compressor So Difficult To Repair?

Unfortunately, since most AC compressors are hermetically sealed, many HVAC specialists are unable to repair them.

An airtight seal implies that all compressor components are enclosed in an airtight metal container. The AC maker can only open the container.

The advantage of hermetically sealed compressors is that they do not leak harmful refrigerants. Inhaling any refrigerant can cause significant respiratory issues.

Due to the tools and time required for a professional to open the container and replace the compressor, changing a compressor is often less cost-efficient than replacement.

Considering an AC replacement? Read this first: How to choose a central air conditioner.

How do I know My Compressor has problems?

Don’t panic if your central AC stops functioning as well as it used to. Although an HVAC technician can help you identify the problem, there are some warning signs to look out for.

They include:

- AC is removing warm air

- Little airflow is coming from your AC

- Weird clicking noises

- Regular tripping of your circuit breaker.

How much is a central AC Unit Compressor?

The cost of a central AC compressor will vary depending on the size and even the central AC brand. However, the price can range from as little as $800 to as much as $ 3,500.

What does a central AC compressor do?

Simply put, the compressor compresses the refrigerant, which then absorbs heat and humidity from the indoor space.

Is it worth replacing a central AC compressor?

If it is only a few years old and has been constantly malfunctioning, then it’s time to activate that warranty. However, if it is older than ten years, then you should look for “home AC installation near me.” services.

It is 100% worth replacing a malfunctioning unit. You do not want to live with the burden of a malfunctioning one.

Final Thoughts on Central Air Conditioning Compressor

At this point, you understand the critical importance of a central AC compressor. You know the potential problems it can face and possibly how to address them.

For proper air cooling, the central AC unit’s compressor must be in good working condition. If you are experiencing any issues, please feel free to contact us.

call 661-888-0248

Contact us 24/7 for HVAC services!

Sources

https://www.energy.gov/energysaver/central-air-conditioning